Commercial Asphalt Paving: Long-Lasting Solutions for Business Infrastructure

Commercial asphalt paving is a foundational aspect of modern business infrastructure. From shopping centers and office complexes to airports and manufacturing facilities, quality asphalt work ensures functionality, safety, and visual appeal. Unlike residential paving, commercial projects demand specialized materials, technology, and application techniques to support heavy loads and constant traffic.

This guide provides a comprehensive overview of commercial asphalt paving, highlighting its key benefits, addressing common business challenges, and introducing industry-standard products to consider.

What is Commercial Asphalt Paving?

Commercial asphalt paving involves the preparation, installation, and maintenance of asphalt surfaces used in business environments. These include parking lots, industrial yards, highways, loading docks, and runways. The objective is to deliver a surface that can support heavy-duty traffic, resist weather conditions, and maintain its structural integrity for decades.

High-traffic areas require precise engineering and industrial-grade asphalt mixtures. This includes proper grading, base preparation, and paving to ensure the asphalt can handle the load without breaking down.

Why Businesses Choose Asphalt Over Other Materials

Insert image of the product format.

Asphalt is the preferred surface material for commercial settings for several compelling reasons:

- Durability: A professionally installed asphalt surface can last up to 30 years with proper maintenance. It handles vehicle weight and constant motion with minimal damage.

- Cost-Effective Maintenance: Asphalt is easier and cheaper to repair than concrete. Cracks can be sealed quickly, and overlays can refresh worn surfaces without tearing out the entire layer.

- Fast Installation: Businesses often need quick project turnarounds. Asphalt can be applied and cured faster than concrete, minimizing operational downtime.

- Recyclability: Modern asphalt contains reclaimed materials, making it one of the most eco-friendly paving solutions available today.

- Smooth Ride Quality: Asphalt surfaces reduce vibration and noise, creating a safer and more comfortable driving or walking experience.

Benefits of Advanced Asphalt Paving Technologies

Over the last few decades, asphalt paving technology has evolved dramatically. Today’s solutions involve enhanced mixtures, advanced compaction equipment, and environmentally responsible practices.

Insert image of the product format.

Improved Structural Strength

One of the biggest advances in modern asphalt paving is the incorporation of stronger aggregate mixes and binders. These allow asphalt to better resist deformation and rutting, especially in areas where heavy trucks or forklifts operate daily.

Some companies even use fiber reinforcement in their asphalt blend, which improves tensile strength and reduces cracking over time.

Better Weather Resilience

Old asphalt used to deteriorate rapidly under UV exposure, water penetration, and thermal expansion. Current paving technologies address these weaknesses through additives and surface treatments that repel water and resist oxidation.

Many paving contractors now offer permeable asphalt surfaces that improve drainage, reducing the risk of water pooling and ice formation in colder regions.

Common Business Problems Solved by Asphalt Paving

Poor-quality surfaces can become a business liability. Cracked pavement, potholes, and uneven parking lots not only affect the customer experience but can also result in injuries and lawsuits.

Problem 1: High Maintenance Costs Due to Inferior Materials

Low-quality paving materials degrade quickly under heavy use, leading to frequent repairs. Commercial-grade asphalt, reinforced with polymers and engineered aggregates, offers a longer lifespan with fewer touchups.

Problem 2: Unsafe or Unattractive Business Environments

A poorly maintained parking lot or loading dock presents hazards. Tripping risks, vehicle damage, and inefficient traffic flow all impact safety and customer satisfaction. A properly paved asphalt surface enhances both functionality and aesthetics.

Problem 3: Drainage and Weather Damage

Standing water is a major cause of pavement failure. Modern commercial asphalt is designed to either drain water through sloping or allow water to permeate through the surface to reduce surface runoff.

In-Depth Look at Five Commercial Asphalt Paving Products

To understand what options exist in the market, here are five standout asphalt paving solutions used by commercial facilities today.

1. Heavy-Duty Industrial Asphalt Mix

This type of asphalt is designed for distribution centers, airports, and shipping yards. It contains a high concentration of crushed stone and polymer additives, which improve load-bearing capacity and cracking resistance.

Details:

- Ideal for sites exposed to frequent heavy truck traffic

- Can withstand extreme temperature variations

- Often used in multi-layered paving with strong base courses

2. Recycled Asphalt Pavement (RAP) Solutions

RAP is a sustainable and cost-effective alternative that reuses existing asphalt materials. It’s typically blended with fresh asphalt binders to maintain quality.

Details:

- Reduces costs by up to 25%

- Excellent for large-scale parking lots and commercial driveways

- Helps businesses meet green building standards

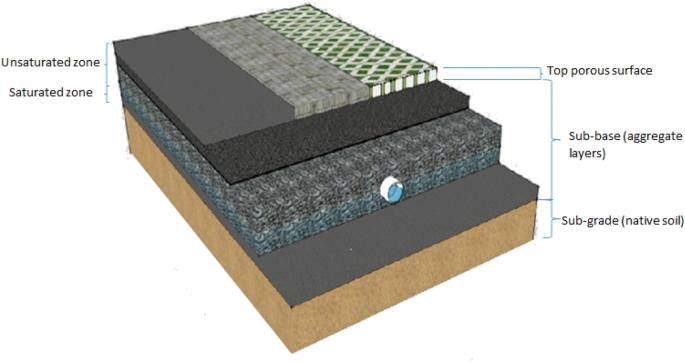

3. Porous Asphalt for Stormwater Management

Porous asphalt is a specialized mixture that allows water to drain directly through the pavement, reducing the burden on stormwater systems.

Details:

- Widely used in environmentally sensitive zones

- Prevents surface runoff and waterlogging

- Enhances site drainage and flood prevention

4. Polymer-Modified Asphalt (PMA)

PMAs include elastomeric polymers in the mix to increase elasticity, making the asphalt more flexible and resistant to cracking.

Details:

- High tensile strength and fatigue resistance

- Suitable for high-stress areas like intersections and ramps

- Prolongs the lifespan of the pavement in urban settings

5. Asphalt with Geotextile Reinforcement

This system incorporates geotextile fabrics between pavement layers to increase structural performance and prevent reflective cracking.

Details:

- Great for overlays and resurfacing projects

- Creates a thermal barrier and strengthens the base

- Used frequently in school campuses, hospitals, and malls

Real-World Use Cases of Commercial Asphalt Paving

Commercial asphalt solutions are applied across a wide variety of industries. Each scenario demands a tailored approach.

Use Case: Shopping Mall Parking Lot

A regional shopping center needed to repave its 200,000 square foot parking area. Using a heavy-duty industrial mix, the contractor installed new base layers, applied thick asphalt overlays, and completed striping in under a week. The result was a durable surface that could handle both vehicles and pedestrians safely.

Use Case: Hospital Emergency Entrance

Hospitals require fast and smooth access for ambulances. A porous asphalt surface was used in the emergency drive-up zone to prevent flooding and ice build-up, ensuring safety year-round.

Use Case: Logistics Hub Yard

At a major logistics hub, the asphalt needed to withstand 24/7 semi-truck traffic. A geotextile-reinforced solution was chosen, paired with deep base compaction. The pavement has shown no signs of failure after three years of continuous use.

How to Choose the Right Paving Solution

Choosing the best commercial asphalt paving product depends on multiple factors:

- Traffic Load: High traffic or heavy equipment areas require stronger mixes.

- Climate: Colder climates benefit from flexible and crack-resistant asphalt.

- Budget: While high-performance options cost more upfront, they often require less maintenance.

- Environmental Regulations: Some regions mandate eco-friendly solutions like RAP or porous asphalt.

Professional paving contractors will assess your needs and recommend the right blend, thickness, and installation strategy to suit your project.

How to Buy Commercial Asphalt Paving Services

Buying asphalt paving services for a business involves more than just hiring a contractor. Here’s how the process typically works:

- Consultation and Site Evaluation: Contractors visit your location to measure, assess, and identify potential issues like drainage and soil strength.

- Proposal and Quote: Based on the evaluation, you receive a detailed proposal including cost estimates, project timeline, materials used, and warranties.

- Scheduling and Execution: Once the quote is accepted, the project is scheduled around your business hours to minimize disruption.

- Maintenance Planning: Many providers offer maintenance services such as sealcoating, crack filling, and resurfacing on a scheduled basis.

Look for providers with verified experience in commercial projects, proper licensing, and positive reviews from similar industries.

Frequently Asked Questions (FAQ)

Q1: How long does commercial asphalt paving take to install?

Installation timelines vary based on project size and conditions, but most commercial paving jobs are completed in 2–7 days, including curing and striping.

Q2: What’s the difference between residential and commercial asphalt?

Commercial asphalt typically involves thicker layers, stronger base preparation, and higher-quality mixes to support heavy-duty vehicles and larger surface areas.

Q3: How often should a commercial asphalt surface be maintained?

Routine maintenance,e such as sealcoating, should be done every 2–4 years. Crack sealing and patch repairs may be required annually, depending on traffic volume and climate.